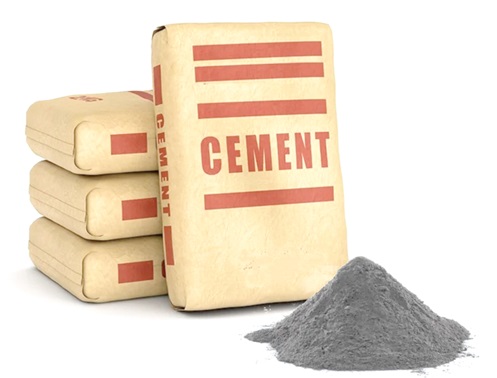

Ghana’s construction sector is undergoing a transformative shift with the introduction of Pozzolana cement—a locally-produced, eco-friendly alternative to traditional Portland cement. Developed through extensive research by the Council for Scientific and Industrial Research’s Building and Road Research Institute (CSIR-BRRI), Pozzolana cement addresses the nation’s housing deficit and promotes sustainable infrastructure development.

What is Pozzolana Cement?

Pozzolana cement is a blend of natural materials, primarily clay and palm kernel shells, which, when combined with lime, exhibit cementitious properties. This innovative product not only reduces reliance on imported clinker but also offers enhanced durability, making it suitable for various construction projects across Ghana.

Economic and Environmental Benefits

- Cost-Effective Construction: By replacing up to 30-40% of traditional cement components, Pozzolana cement can reduce construction costs by 18-20%, making housing more affordable for Ghanaians.

- Foreign Exchange Savings: The adoption of Pozzolana cement could save Ghana approximately $30 million annually by decreasing the importation of clinker and gypsum.

- Environmental Sustainability: Utilizing local materials reduces carbon emissions associated with cement production and transportation, contributing to Ghana’s climate change mitigation efforts.

Production and Availability

Pozzolana Ghana Limited (PGL), in partnership with CSIR-BRRI, operates a production facility in Gomoa Mprumem, Central Region, capable of producing 5,000 bags of cement daily. Despite its potential, the factory requires an investment of $4 million to reach optimal production levels and meet growing demand.

Challenges and the Way Forward

While Pozzolana cement offers numerous advantages, its adoption faces challenges such as limited awareness among contractors and consumers, and inadequate marketing strategies. To overcome these hurdles, stakeholders advocate for:

- Government Support: Incorporating Pozzolana cement in public construction projects to promote its usage.

- Training and Education: Conducting workshops for contractors and builders to demonstrate the benefits and application techniques of Pozzolana cement.

- Private Investment: Attracting investors to fund the expansion and modernization of production facilities to meet national demand.

Be the first to leave a comment